|

Fiber Optics Knowledge

Why use fiber?

The biggest advantage of optical fiber is the fact it is the most cost effective means of transporting information.

Fiber can transport more information longer distances in less time than any other communications medium.

In addition, it is unaffected by the interference of electromagnetic radiation which makes it possible to transmit information and data with less noise and less error.

|

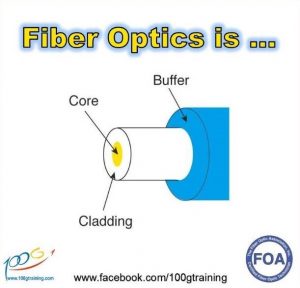

Fiber Optics is the communications medium that works by sending optical signals down hair-thin strands of extremely pure glass or plastic fiber.

The light is “guided” down the center of the fiber called the “core”.

The core is surrounded by a optical material called the “cladding” that traps the light in the core using an optical technique called “total internal reflection.”

The fiber itself is coated by a “buffer” as it is made to protect the fiber from moisture and physical damage.

|

The power of fiber optic communications connects the world.

The red lines are all the submarine fiber optic cables that connect the places where people live and provide their communications links to each other.

Fiber optics connects the world under the seas and over the land. Virtually all communications at some point travels via fiber optic cable.

|

The usage of fiber optic is growing in:

1) Internet Backbone, 2) Wireless System Backhaul, Antenna Connections, 3) Smart Grid – Utilities, 4) Metropolitan Networks, 5) Security Systems 6) Data Centers, 7) Fiber To The Home (FTTH), 8) OLANs…and more!

Fiber use is growing in many areas – even wireless depends on fiber optics for its communications backbones.

|

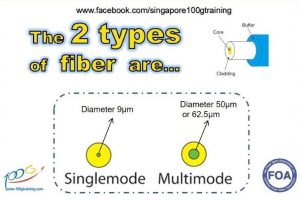

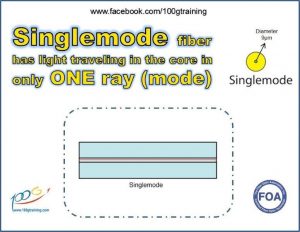

The two types of fiber are Singlemode and Multimode.

Within these categories, fibers are identified by their core and cladding diameters expressed in microns (one millionth of a meter).

For example e.g. 9/125 micron Singlemode fiber and 50/125 micron Multimode fiber or 62.5/125 micron multimode fiber.

9micron, 50 micron, 62.5 micron represent the diameter dimension for core

125 micron is the diameter dimension for cladding

|

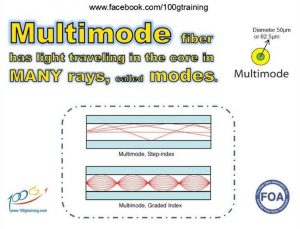

Multimode fiber has light traveling in the core in many rays, called modes. It has a larger core (almost always 50microns or 62.5 microns) which supports the transmission of multiple modes (rays) of light.

Graded index MM is used for lower speed data networks like LAN or security systems.

With laser or LED sources at wavelengths of 850nm and 1300 nm

|

Singlemode fiber has a much smaller core, only about 9 microns, so that the light travels in only one ray (mode.)

It is used for long distance, telephony, Telco outside plant, CATV and FTTH with laser sources at 1310nm and 1550 nm.

It can go very long distances at very high speeds.

|

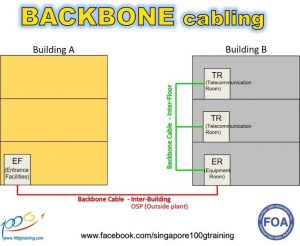

Backbone cabling is the inter-building and intra-building cable connections in structured cabling between entrance facilities, equipment rooms and telecommunications closets.

It is also a larger transmission line that is capable of carrying the majority of traffic on the network at the highest speeds. The backbone often connects large networks or long-distance interconnection.

|

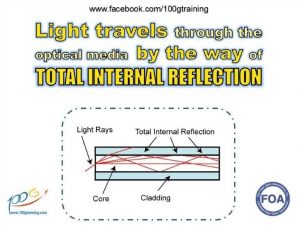

How light travels through the optical media?

When light traveling in the core hits a boundary at an angle larger than the “critical angle” for the boundary, the light will be completely reflected. This confine light in the core.

By making the core of the fiber of a material with a slightly higher refractive index, we can cause the light in the core to be totally reflected at the boundary of the cladding for all light that strikes at greater than a critical angle determined by the difference in the composition of the materials used in the core and cladding.

|

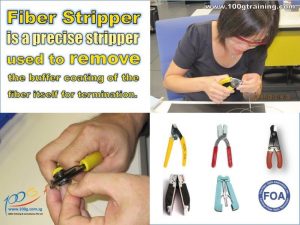

What is a Fiber Stripper?

A Fiber Stripper is a precise stripper used to remove the buffer coating of the fiber itself for termination.

Please visit OUR MAIN WEBSITE https://www.100gtraining.com

If you want more information, please email to admin@100g.com.sg

|

What is cleaving? What is an optical cleaver?

Cleaving is the process by which an optical fiber is “cut” or precisely broken for termination or splicing.

A fiber cleaver is a tool that precisely “breaks” the fiber to produce a flat end for polishing or splicing.

|

Why it is important to have a good cleave?

It is very important to cleave the fiber properly in order to get good fiber optic splices or terminations.

You waste a lot time and efforts when you have a bad cleave, you have to do again.

Many time, it takes longer to splice or the test results are bad because the cleaver is not good enough, therefore having a good cleaver is a good investment.

You want to share to your friends who are splicing FO cable or terminating the pre-polished connectors with internal splices because this information is so helpful & important.

|

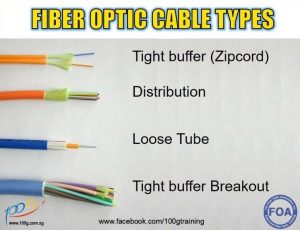

There are 4 major types of cables; Tight buffer comes in simplex or zipcord versions, Distribution cables, Loose tube cables and Tight buffer Breakout cables.

Besides these, there are Ribbon Cable, Armored Cable, Aerial cable, and many more types such as Air-Blown Fiber, Hybrid and Composite Cables etc.

|

Why FO armored cables are used? It is used because of their strong jackets to withstand crushing and rodent penetration.

Armored cable adds metal or dielectric armor over cable, typically to prevent rodent damage in direct burial installations.

It is also can be used in any application to prevent crushing, even indoors, for example in raised floors where there are many heavy cables already installed and potential of crushing the cable is high.

|

Fiber Optic Outdoor cables are generally black but premises cables are color-coded.

De facto standard color codes for cable jackets have been yellow jackets for singlemode and orange jackets for multimode.

With two multimode fibers now in common use, 62.5/125 and 50/125, and two versions of 50/125 fiber, it’s important to follow the TIA-598 standard to prevent mixing up cables.

|

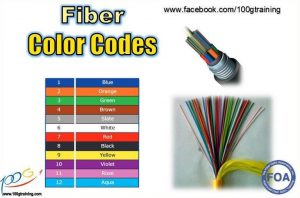

Inside the cable or inside each tube in a loose tube cable, individual fibers will be color coded for identification (color format as shown in picture).

The color code used in fiber optics, resembles that of copper cabling. The major difference is 12-color sequence as oppose to 10-color for copper. The sequence of colors is the same, with addition of two colors – Rose (11-th) and Aqua (12-th).

|

It is important to follow the fiber color code when splicing or installing the connectors to the panel as shown in picture.

If the color format is not followed accordingly from one end to the other end of the installation, you will FACE CONTINUITY AND POLARITY ISSUES. There will be a mix-up of the ports and you have to spend time to troubleshoot and rectify them.

Following the code helps you save time, better cable management and reduce human errors.

|

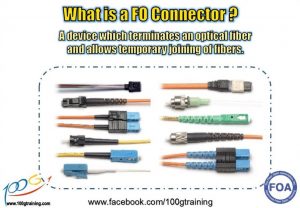

What is a FO connector? In the fiber optic jargon, it is NOT called “a plug and socket” but term as a connector.

A connector is a device which terminates an optical fiber and allows temporary joining of fibers.

|

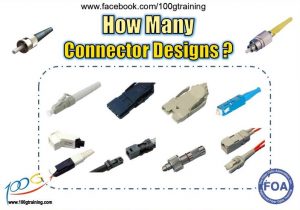

There are over 100 unique connector designs being offered in the history of fiber optics.

Most have faded from use or never became popular, so only a few connector styles dominate today’s networks.

Multimode installations generally use the ST or SC connector, with a growing number of LC SFF (Small Form Factor) connectors.

LC has become the standard for transceivers at 1Gb/s and faster. Singlemode applications use mostly SC or LCs, but many installations are still using older designs.

|

FO connector color code :- The TIA 568 color code for connector bodies and/or boots is Beige for multimode fiber, Blue for singlemode fiber, and Green for APC (angled) connectors.

The “normal” colors for connectors are as shown in the picture, but other colors are sometimes used, especially for multimode. The thing to remember is green means APC and it CANNOT be mated with other types of connectors.

Please visit OUR MAIN WEBSITE https://www.100gtraining.com

If you want more information, please email to admin@100g.com.sg

|

How to join optical fibers?

First, we can join with connectors that can mate two optical fibers to create a temporary joint. The connector can also be connected to transmitters and receivers.

Second, we can join with splices which create a permanent joint between the two fibers.

|

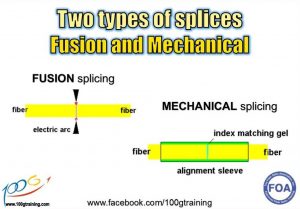

2 Types of Splices:-

1)Fusion splicing is done by welding the two fibers together, usually with an electrical arc with an automated splicer which aligns the fibers exactly.

2)Mechanical splices use an alignment fixture to mate the fibers and either a matching gel or epoxy to minimize back reflection.

|

What is Fusion Splicing?

Fusion splicing is the process of fusing or welding two fibers together usually by an electric arc.

Fusion splicing is the most widely used method of splicing as it provides for the lowest loss and least reflectance, as well as providing the strongest and most reliable joint between two fibers.

|

What is Mechanical Splicing?

Mechanical splicing is mating two fibers together by using an alignment fixture and reducing loss and reflectance with a transparent gel or optical adhesive between the fibers that matches the optical properties of the glass.

Mechanical splices generally have higher loss and greater reflectance than fusion splices, and because the fibers are crimped to hold them in place, do not have as good fiber retention or pull-out strength.

|

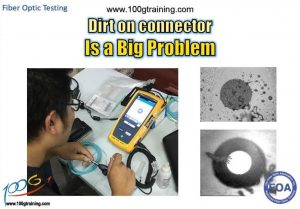

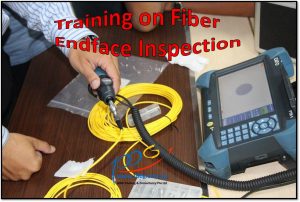

It is important to do a visual inspection of connector because you want to make sure the end face of the connector is good and there is no dirt or scratches on the core of the optical fiber.

Do this by using a hand held or video fiber microscope to look at connector ends for contamination and damage such as dirt, oil, scratches and epoxy.

All connectors–even brand new jumpers with a factory finish–should be cleaned prior to mating to prevent dirt moving from one connector to another; connector contamination as small as 0.001 mm can cause high loss and poor reflectance.

|

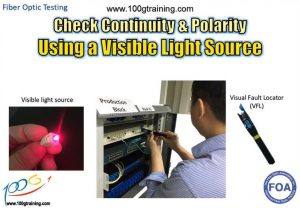

A basic fiber test consists of using a visible light source to check for end-to-end continuity of a fiber, and connector polarity.

This type of tester is called a visual fault locator (VFL), and uses a visible red laser to visually detect breaks in continuity caused by fiber bends, breaks and faults.

It can also be used to check the polarity of duplex and MPO cables.

|

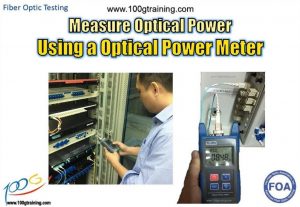

An optic power meter is (OPM) an instrument that measures optical power emanating form the end of a fiber.

It is used to accurately measure the power of fiber optic equipment or the power of an optical signal passed through the fiber cable (power measurement).

It also helps in determining the power loss incurred to the optical signal while passing through the optical media (loss testing).

|

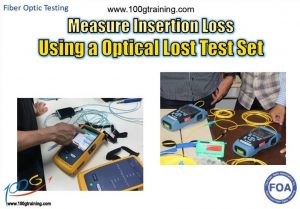

Testing for loss (also called “insertion loss”) requires measuring the optical power lost in a cable (including fiber attenuation, connector loss and splice loss) with a calibrated light source and power meter (LSPM) or optical loss test set (OLTS.)

Loss of a cable is the difference between the power coupled into the cable at the transmitter end and what comes out at the receiver end.

|

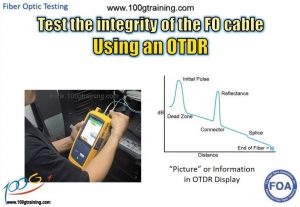

The Optical Time Domain Reflectometer (OTDR) is useful for testing the integrity of fiber optic cables.

It can verify splice loss, measure length and find faults.

The OTDR is also commonly used to create a “picture” of fiber optic cable when it is newly installed.

|

DIRT on connector is the biggest problem – CLEAN and inspect EVERY connection.

Picture shows a fiber optic inspection microscopes is used to inspect the end face of an optical fiber connector for dirt, scratches or other defects.

Please visit OUR MAIN WEBSITE https://www.100gtraining.com

If you want more information, please email to admin@100g.com.sg

|

There are different methods used to clean connector; such as Wet (with alcohol and dry) and Dry (click and clean)

Dry fiber optic cleaning tools (one click) are easiest to use in the field.

You must never assume that factory-installed connectors are perfect or stay clean. Dirt is the #1 enemy of fiber optic connectors because it can cause loss and reflectance, even damage connectors.

|

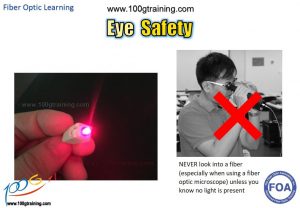

Eye safety– NEVER look into a fiber unless you know no light is present – use a power meter to check it. You should always be careful with your eyes, especially when using a fiber optic microscope.

|

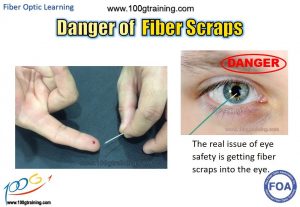

The broken ends of fibers and scraps of fiber created during termination and splicing can be extremely dangerous. The ends are extremely sharp and can easily penetrate your skin.

The real issue of eye safety is getting fiber scraps into the eye. If they get into your eyes, they are very hard to flush out and will probably lead to a trip to the emergency room at the hospital. Whenever you are working with fiber, wear safety glasses!

|

Training is important. It allows you to pick up knowledge, skills and the right attitude.

Please visit OUR MAIN WEBSITE https://www.100gtraining.com

The next Fiber Optic Training CFOT is from 29th to 31st Oct 2025.

If you have any questions or need more information, please email to admin@100g.com.sg